This chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 ContaminantsE10 Eaves (insulation at ceiling level) E11 Eaves (insulation at rafter level) E12 Gable (insulation at ceiling level) E16 Corner (normal) E17 CornerTo continue using and enjoying our platform, please register here to receive unlimited access to inspiration, homeware products, professionals and

Certified Thermal Details And Products Scheme Bre Group

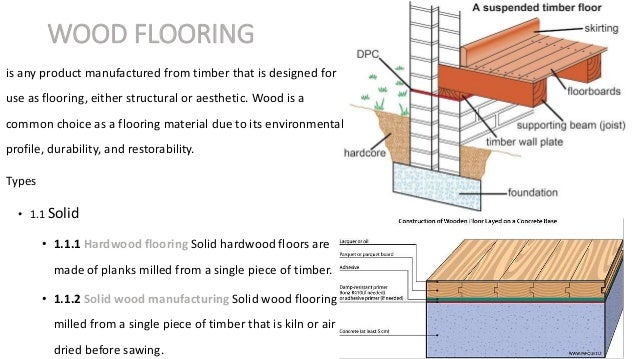

Suspended timber floor detail uk

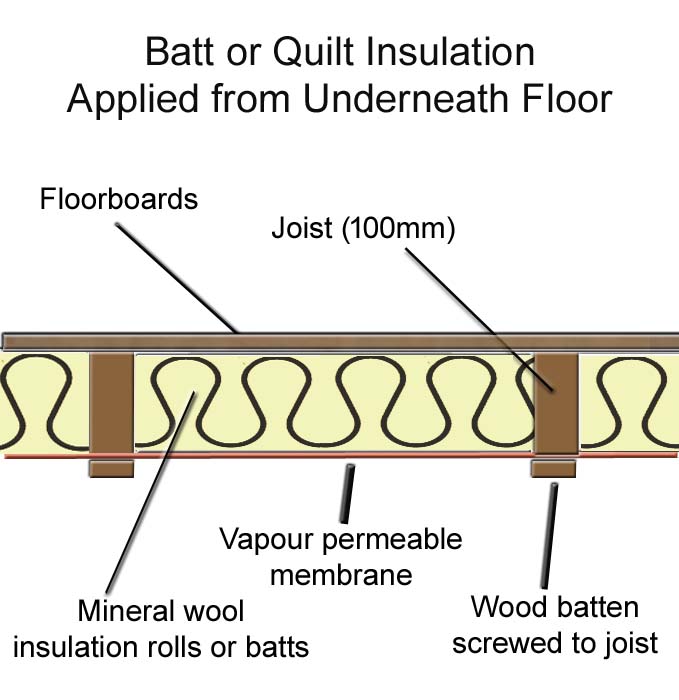

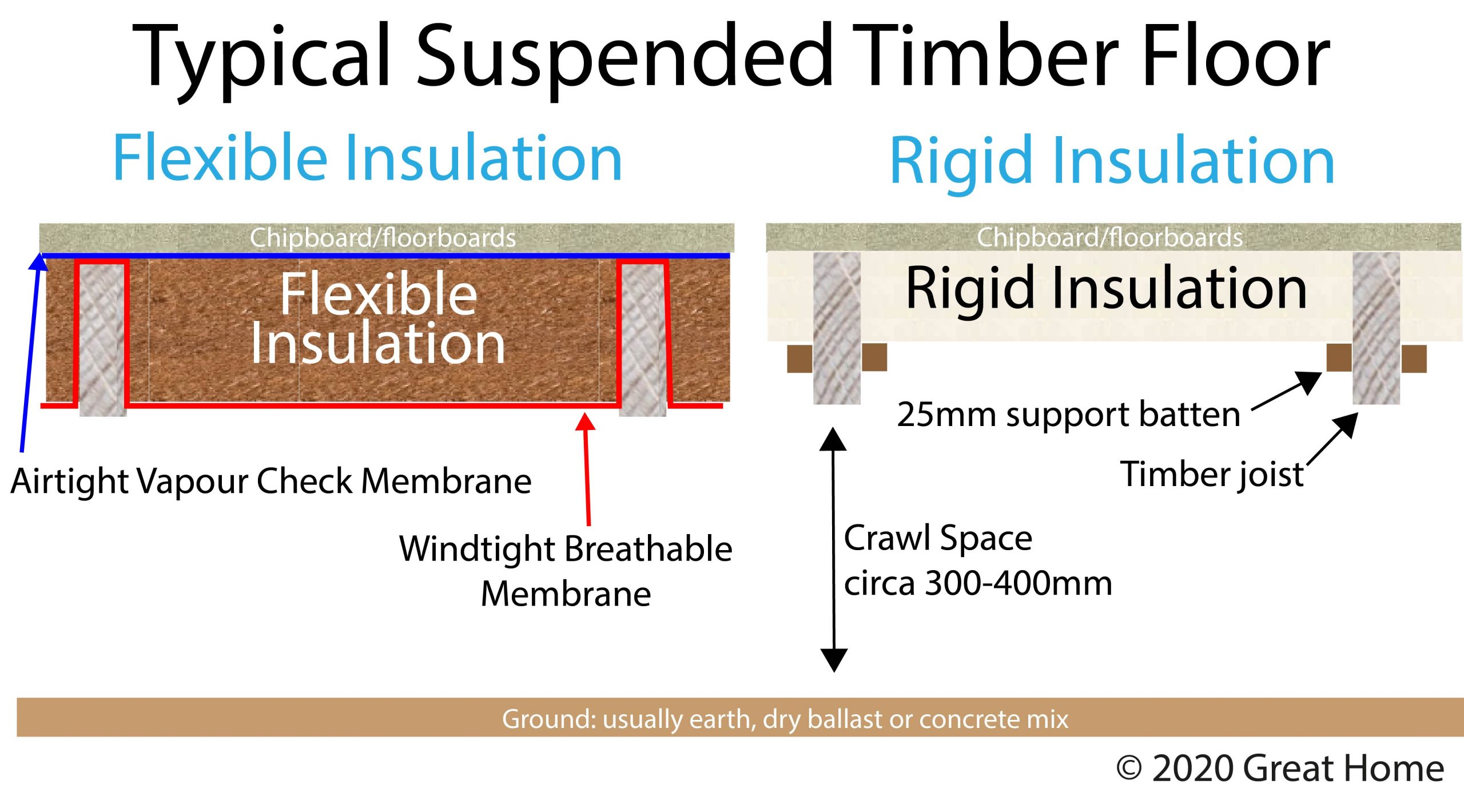

Suspended timber floor detail uk-The main driver for installing suspended timber floor insulation will be to improve thermal performance To plan what thickness of insulation you'll need for a suspended timber floor you must calculate its UValue In England and Wales building regulations suggest the floor should achieve a UValue of 025 W/m2K or less, if possible To define this, you'll also need to work outSelecting Timber Floors Floor Structure Floating Floor type Underfloor Heating Thickness Robust Detail Solid timber joist Timber deck on resilient battens No 384mm EFT2 4235mm EFT8 Engineered Ijoist Timber deck on resilient battens No 403mm EFT1 4235mm EFT7 Wet screed No 4516mm EFT4 Dry screed board Yes 346mm EFT5 Metal web joist Timber

Www Scoilnet Ie Uploads Resources 246 Pdf

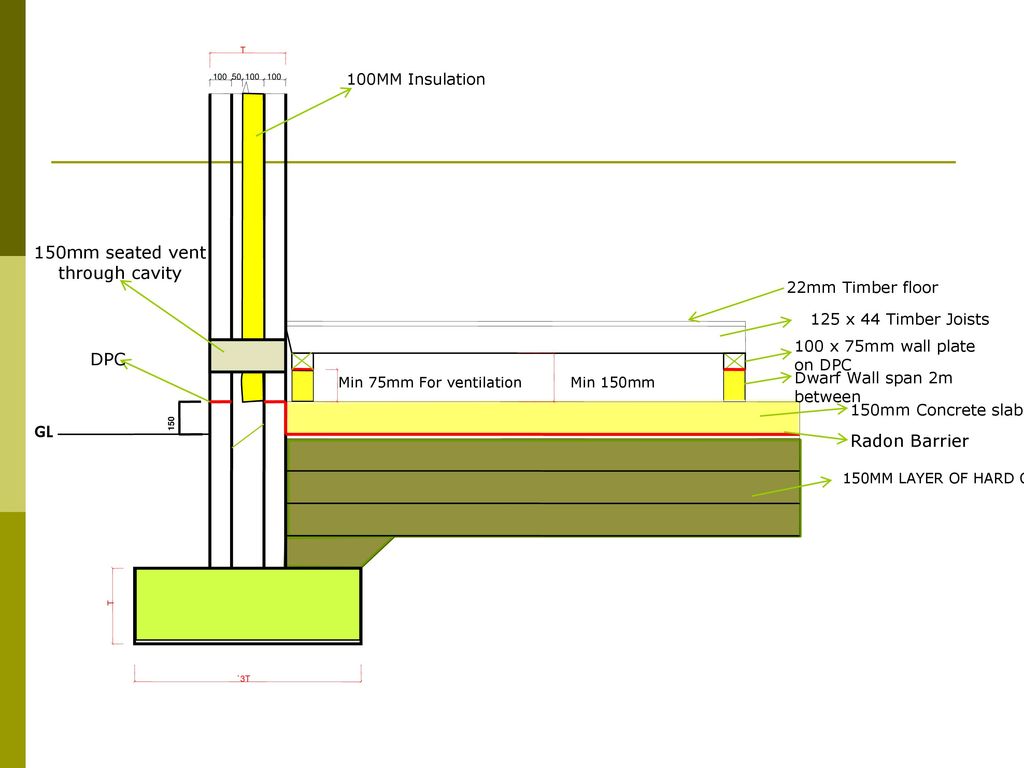

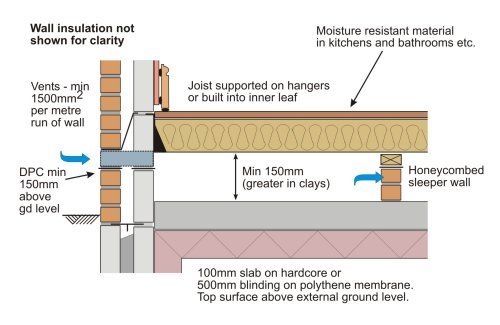

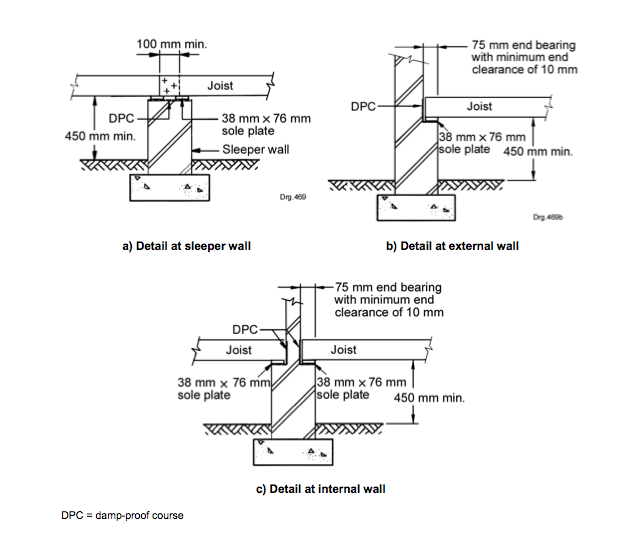

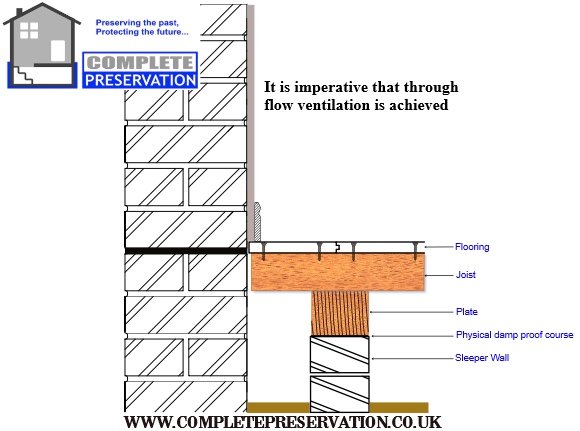

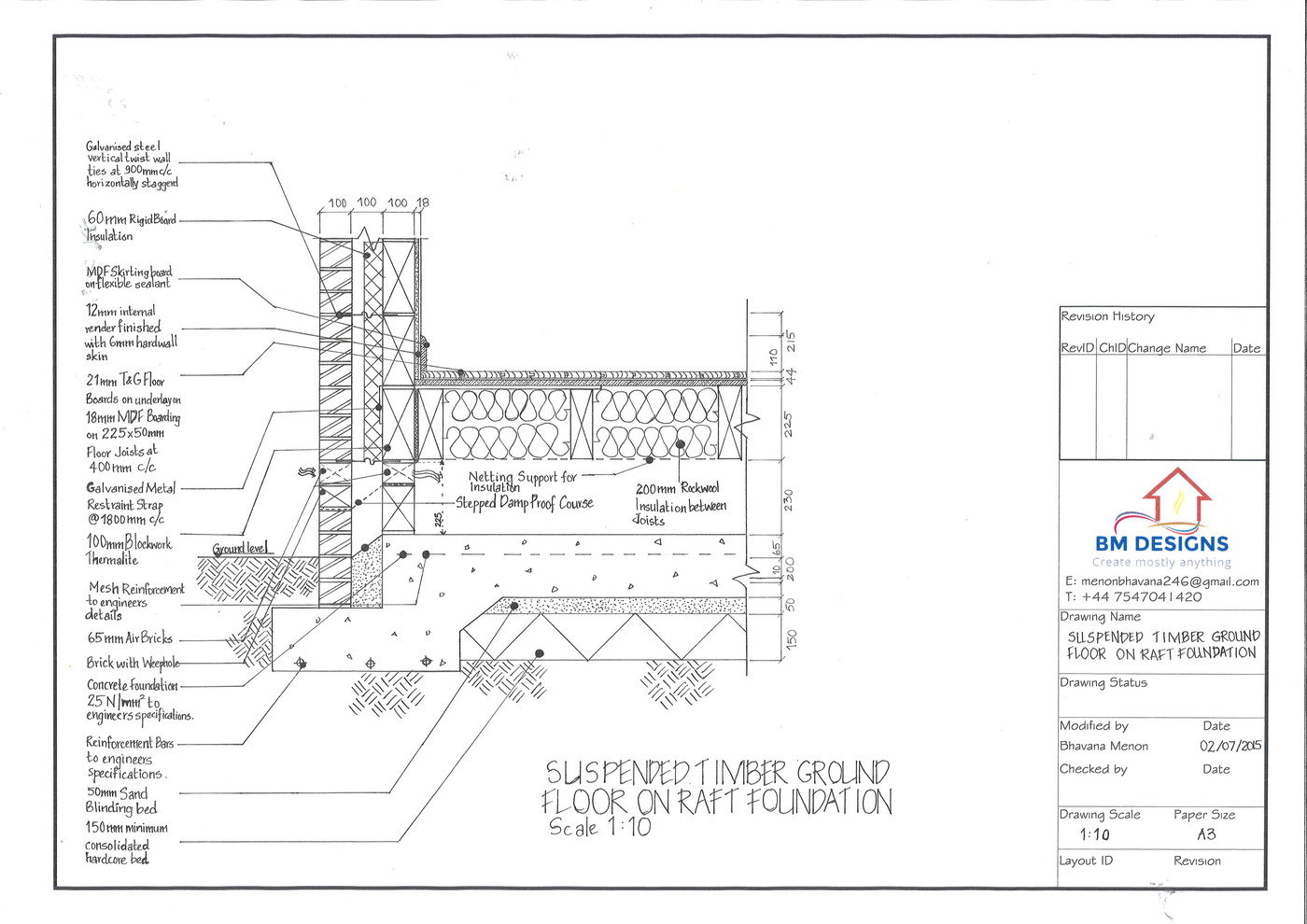

Section for full details 1 1 1 1 2 2 2 2 2 3 3 Timber joists ceilings and separating / compartment floors 65 22 book 6_jan10ac01 Introduction v3qxd 1945 Page 309 310 wwwgyprocie 1 2 3 Table 3 Dimensions and performance1 noncombustible board linings 4 5 6 Detail Board type Flooring Joist Joist Insulation Fire Performance board centres width Basement / ground floor of timber 1 Auditorium – dances and dramas Filling of selected earth wall Bridging joists Floor Boards FLDPC 12 to 18mGL Wall plates Sleeper wall 10 to 15 mm Cement course 5 Precautions • Soil below timber floor – covered with PCC 124 (100 to 150 mm thk) • DPC – exterior wall top of the sleeper wall • Well seasoned timber is used •Where existing suspended timber floor air bricks are covered by new extension, ensure cross ventilation is maintained by connecting to 100mm dia upvc pipes with 100mm concrete cover laid under the extension Pipes to terminate at new 65mm x 215mm air bricks with cavity tray over Construction Detail Drawings Quick Links As well as the drawings shown with the relevant

E6 Intermediate floor within a dwelling;Guidance Table 7 Examples of insulation for floating floors Suspended timber ground floor Guidance Diagram 12 Typical section through a suspended timber ground floor Guidance Table 8 Examples of insulation for suspended timber ground floors Garage ground bearing concrete floor Guidance Diagram 13 Typical section through a ground bearing garage floor andUntil the development of suspended timber ground floors in the early 18th century, solid floors had been the dominant form of construction By the beginning of the th century, the ground floors of most houses comprised boarded suspended timber floors on sleeper walls, with solid floors of quarry tiles laid

E18 P1 Party wall between;Learn How To Design A Cantilevered Floating Staircase Stairs Suspended Timber Floor Detail Drawing, Block And Beam Floor Google Search House Extension Plans 23 Best Architectural Detail Images Architecture DetailsTIMBER FRAME STANDARD DETAILS SEPTEMBER 09 Building 1 Grosvenor Court, Hipley Street OLD WOKING, SURREY Tel 44 (0) 14 Fax 44 (0) 14 Email design@silvatecdesigncom Internet wwwsilvatecdesigncom Details on Plan 1 External Wall 11 External corner 12 Reentrant corner 13 Separating wall junctions 14 Non loadbearing wall

A Best Practice Approach To Insulating Suspended Timber Floors Ecological Building Systems

Borders Underfloor Heating Supply Underfloor Heating For Suspended Timber Floors

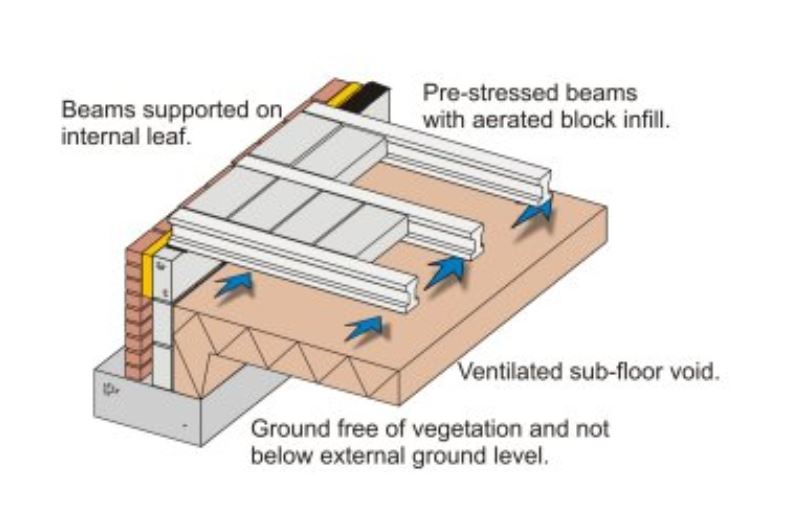

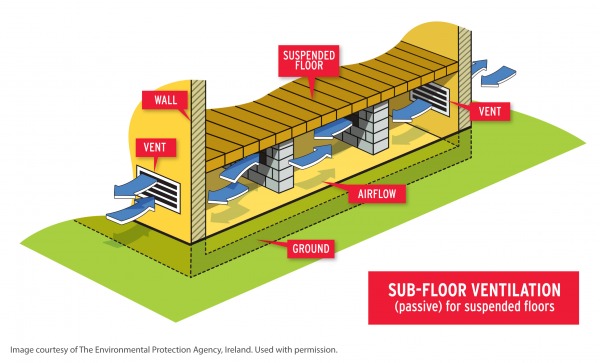

Timber joists are widely used within internal floor and separating floor construction, both in residential and commercial applications Our range of timber joist floor solutions include cavity insulation, highperformance Gyproc plasterboards and Gypframe sound insulating bars Our solutions maximise acoustic and fire performance, to both meetMany buildings with suspended timber floor suffer from rot and insect attack in the ground floor timbers due to poor sub floor ventilation We look at this more thoroughly in our air bricks and air vents project , but quite simply if air bricks become blocked with debris or ground levels are raised this cuts off the air flow and water leaks may also occurSuspended concrete floor This construction is similar to the timber floor above, but uses either precast concrete planks or small precast concrete beams with concrete blocks laid between the beams They can normally span greater distances than timber joists Ventilation is required in the same way as a suspended timber floor

How To Ensure Lateral Support To Walls When Constructing Floors And Roofs

Concrete And Suspended Timber Ppt Download

Construction Studies drawing detail of suspended timber floorFor 35 years, ACTIS has been developing insulation products using effective solutions ACTIS specialises in the design and manufacture of innovative building insulation products for roofs, walls, lofts and floors and offers comprehensive, easy to install, cost effective systems ideal for both refurbishment and new buildSuspended Floor {product_related_downloadscount} RIW/TD/303 SLAB EDGE DETAIL Timber frame pdf RIW/TD/304 DPM RED/DPM BLUE Linking details to other products pdf RIW/TD/305 SHEETSEAL 9000 DPC Cavity tray fixing to solid inner skin Cavity Drain {product_related_downloadscount} pdf RIW/TD/401 AQUA CHANNEL in rebate with masonry

Suspended Floors All You Need To Know Thermohouse

Building Guidelines Underfloor Ventilation Suspended Timber Floors

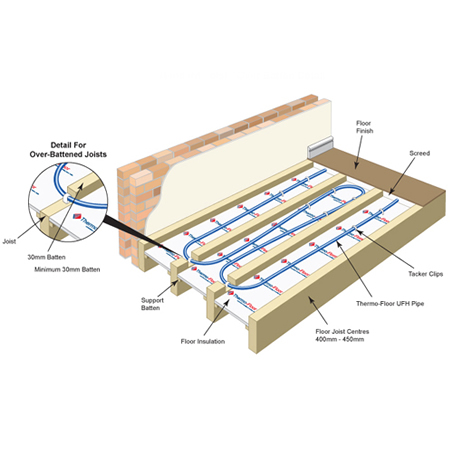

Diagram of suspended timber floor with underfloor heating pipesGround Floor – Hollow or Timber Floor Hollow floors, also known as suspended or timber floors, are simply timber joists suspended across and supported by load bearing walls under the floor The ends of these timber joists are built into, or suspended by joist hangers from the external walls of the property suspended timber floors located above an unheated space, where the insulation is installed below the floorboards or timber decking timber floors situated above an unheated integral garage, unheated

Ptg Flooring Fixing Instructions

Variation In U Value For A Suspended Timber Floor 33 Download Scientific Diagram

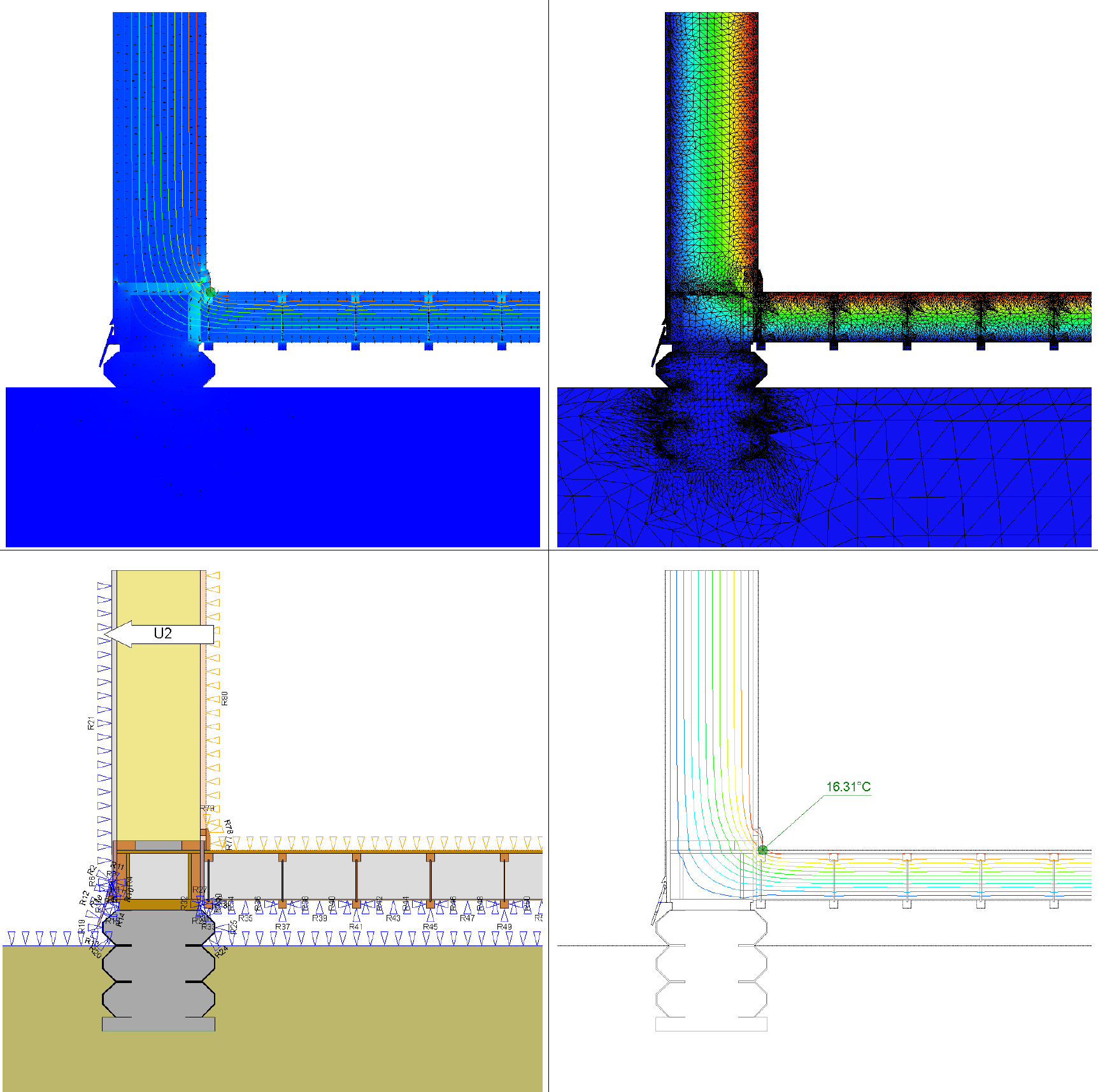

Detail Number Product Name Junction type Developer Wall type Wall Uvalue (W/m 2 K) Floor Uvalue (W/m 2 K) SAP K1 ref BRE Ψvalue (W/mK) BRE Temp factor (ƒ) 9 Suspended ground floor slab insulation below slab Wallground floor junction Scottish Building Standards Masonry 017 013 E5 0119 09 210 Ground bearing floor slab insulation aboveThanks for visiting HouseBuild!Original bungalows had suspended timber floors supported by piles set into the ground On this page Piles;

What Is A Suspended Timber Floor Discount Flooring Depot Blog

Detail Post Floor Details First In Architecture

A suspended floor is a ground floor with a void underneath the structure The floor can be formed in various ways, using timber joists, precast concrete panels, block and beam system or cast insitu with reinforced concrete However, the floor structure is supported by external and internal wallsStudies of the site, carried out in accordance with Chapter 41 'Land quality managing ground conditions' should be taken into account in the design of substructure Where the depth of infill exceeds 600mm, the floor must be designed as a suspended floor, as described in Chapter 52 'Suspended ground floors' (Design) Loadbearing partitions should not be supported off ground bearing floorsTimber suspended ground floors, including the decking material, shall be designed to (a) support self weight, dead loads and imposed loads (b) transmit loads safely to the supporting structure (c) not deflect unduly

Detail At Floor External Door Junction

Suspended Floors Placemakers

To get the timber suspended floor to act as a screeded floor and to give out more heat, the air gap between the insulation and the floor boards should be filled with a lightweight screed mix The infill is normally 101 sand/cement mix at a height of 25 mmWe have a wide range of floor insulation boards, including solid ground floor insulation, suspended floor insulation and soffit insulation We also have insulation boards suitable for more specialist flooring applications, for example heavy duty floor insulation and insulation for cellar and basement floorsAnimated Building Section Details 1 of 21 Strip Foundation & Concrete Ground Floor 2 of 21 Suspended Timber Ground Floor 3 of 21 Linked Floor 4 of 21 Concrete Ground Floor – Timber Frame Wall 5 of 21 Window Cill – Concrete Cavity Wall 6 of 21 Window Cill – Timber Frame Wall 7 of 21 Door Threshold – Concrete Cavity Wall 8 of 21 Eaves Detail – Concrete Cavity Wall 9 of 21

Suspended Timber Floor Construction Studies Q1

Typical External Wall With Suspended Timber Floor Building Energy Rating Air Leakage Testing Castlebar Mayo

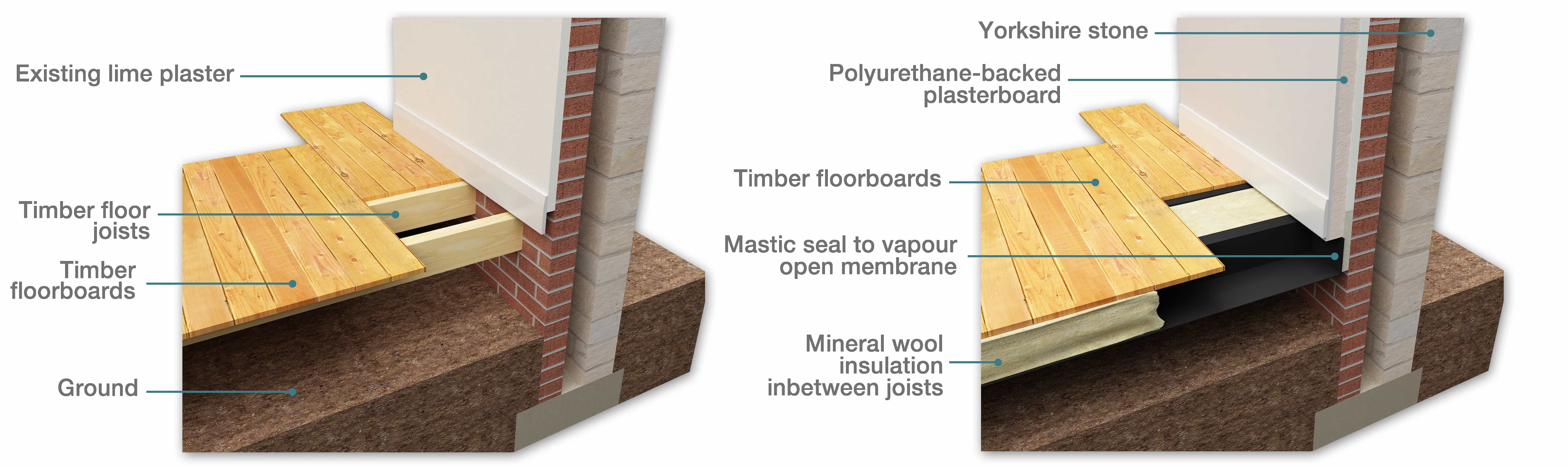

Technical Guidance To help you interpret and apply the NHBC Standards we produce the following Technical Guidance Documents They each expand on and explain a specific part of the NHBC Standards They are designed for use by competent construction industry workers and are for general guidance only They do not constitute professional adviceSuspended Timber Floors Source House Inspector Suspended timber floors are normally made up of timber joists suspended from bearing walls, which are then covered with either floor boards or high quality sheets of tongue and groove To a degree this type of floor can give more comfort when your intention is to carpet the floor and when the floor is well insulated this canSuspended timber floors need to have spaces underneath ventilated via air 'bricks' through the outer walls and gaps in any internal walls so that the air can move across the building underneath the floors to prevent the build up of moisture in the timber which could lead to fungal attack A typical suspended floor is shown below in Fig 1 with the joists resting on sleeper walls at right

Suspended Floor Underfloor Heating Suspended Floor Heating

Insulating Suspended Timber Floors Green Building Store

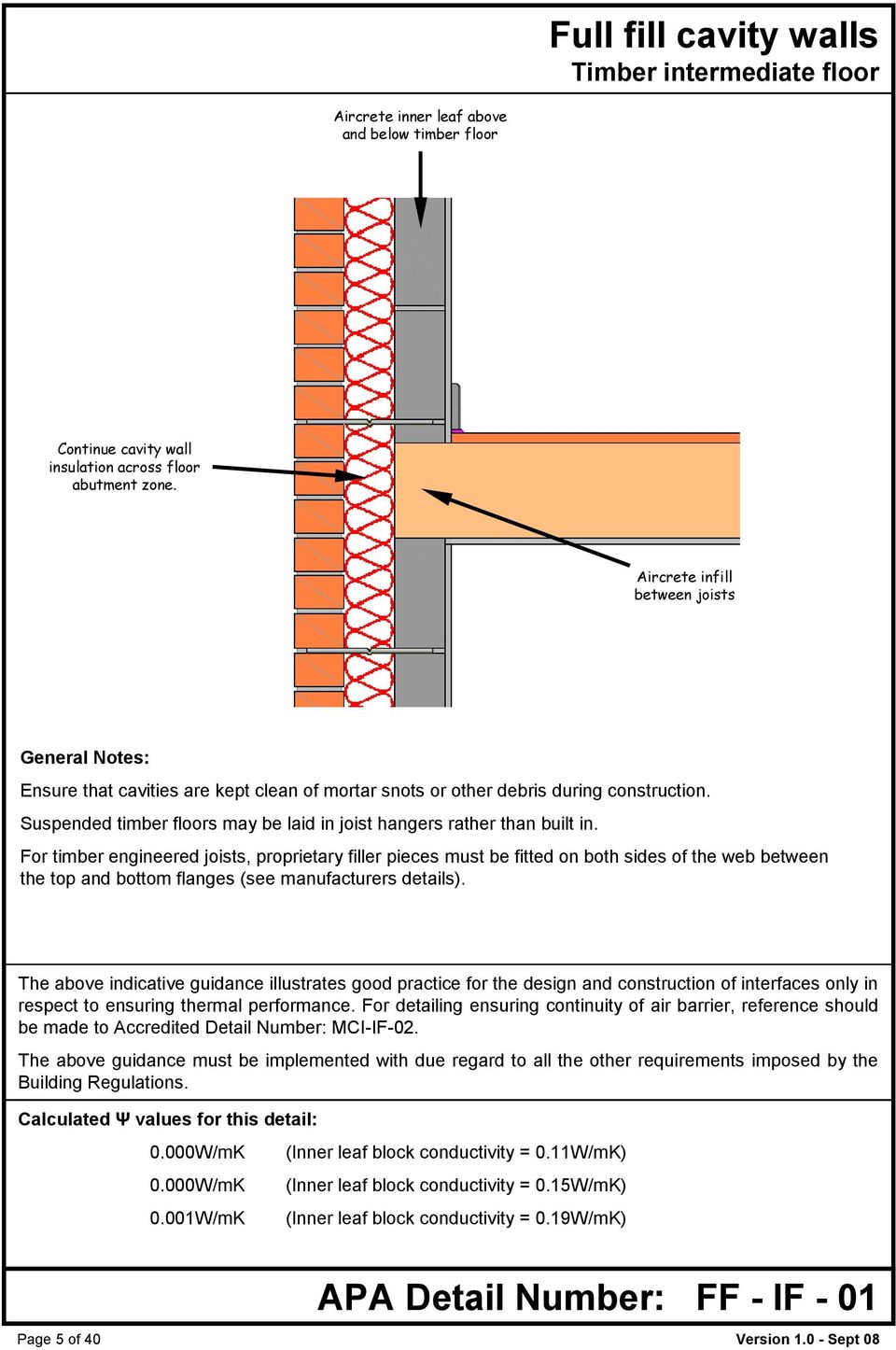

312 Timber Frame – Timber suspended ground floor 313 Timber Frame – Separating wall (junction with external wall) Each detail section must be read in conjunction with the introductory section of the ACD document The example details are not intended as, and should not be used as, standard details for construction Instead, the principles and key element beFloors and ceilings (C06) This section details floors and ceilings systems which cover a multitude of performance requirements in all sectors British Gypsum offers a full range of specifications from simple plasterboard ceilings through to a range of gypsumbased, acoustic suspended ceilings and layin grid systems A suspended timber floor is usually constructed using timber joists suspended from bearing walls, which are then covered with either floorboards or some other for of boarding material The joists are typically laid across the shortest span Ventilation may be provided to the void between the floor and the ceiling below by placing air vents/air bricks within the exterior

Timber Flooring Flat Roof Extension Floor Insulation

Ground Floor Ventilation To Insulated Floor Retrofit Pattern Book

E13 Gable (insulation at rafter level) Sill;The perimeter was either piles with base boards covering the section between the base of the wall and the ground (Figure 1), or a continuous foundation wall of brick or concrete (Figure 2) On sloping sites, ground clearance was often minimal with very limitedVentilation in floors, especially suspended timber floors is very important so as not to facilitate the build up of moisture within the floor structure This moisture build up can cause deterioration not only the timber joists but also any coverings placed over the joists Ventilation in suspended timber floors can be achieved by installing vents below the joist level in opposite walls of the

Download Suspended Ground Floors Suspended Timber Floor Full Size Png Image Pngkit

Pre Grooved Insulation Panels Underfloor Insulated Panels

Existing 170x65mm Timber Joists at 380mm c/c (or New 175x50mm Timber Joists in certain locations see Struct Eng's info for details) 9 75mm Knauf Earthwool Acoustic Roll 10 Knauf Resilient Bars at 450mm c/c fixed up into joists with 38mm Knauf Drywall Wood Screws 11 2 layers of 125mm Knauf Fire Panel fixed to Resilient Bars at 230mm cMetal frame suspended ceiling with gypsum based board, minimum 10 kg/m2 (eg External wall junction with timber floor Masonry outer leaf minimum 100mm thick External wall cavity minimum 50mm ROCKWOOL TCB in cavity satisfies acoustic regulations and acts as a 30 minute fire stop (or 60 minute if cavity greater than mm) Resilient strip where chipboard and resilient plasterboardE7 Intermediate floor between dwelling ;

Source Of The Old Suspended Timber Floor A Location Of The Building Download Scientific Diagram

Suspended Floors All You Need To Know Thermohouse

Precast beam and block floors Site preparation All topsoil and organic matter should be removed from beneath the suspended floor The ground level should be at least the same as the external ground level unless the ground below the floor is free draining Alternatively, a DPM linked to the DPC can be providedTable 2 – Separating floors VFT1™ timber ijoists and floating floor treatment VFT2™ timber solid joists and floating floor treatment VFS1™ steel deck and insitu concrete and floating floor treatment List of Robust Details™ IdciA 13 S_IdciN05 1233 Page 3 4 of 8 April 13® Update Introduction robust details Table 3a – Combinations of Robust DetailsIf the new wall passes through an existing timber floor, the key thing to pay attention to is to ensuring that any new timber that is in contact with or supported by the new wall is above the line of the damp proof course Also, if there is ventilation in the void under a suspended timber floor then air bricks in the wall are likely be needed to maintain air flow through the void

Diy Conservatory Shop Suspended Timber Floor Base

Q Tbn And9gcsoo00pmp Jo39lntwqiman Kyqnkiizr2egma 29un93tjzu39 Usqp Cau

Junction E5 Ground floor; The BRANZ Technical Helpline often receives queries for designing and building suspended timber floors and dealing with uplift Nine of the most common questions are answered here a031 2 online Figure 1 Suspended timber floor joist layout (redrawn from NZS Figure 72) Figure 2 Lateral support offset from brace line (redrawn from NZS Figure Timber deck finish can also be used – if this is specified a vapour control layer must be included in the design under the timber deck A void is left under the floor of at least 150mm between the soil and underside of the beam If heavy clay soil is present it is good practice to increase the void depth to as much as 225mm or possibly more

Certified Thermal Details And Products Scheme Bre Group

Www Jablite Co Uk Wp Content Uploads 16 12 Jabfloor Insulation Suspended Timber Floor Pdf

Suspended timber floors, which are typically found in older houses, are normally made from timber floorboards which are then attached to joists just above the foundations of a house This creates a small gap and allows ventilation and air movement to prevent damp forming in the timber joists It's also common to have suspended concrete floors in a domestic andA selection of floor detail drawings including block and beam floors, timber suspended floors, solid ground floors and upgrade floor details Drawings are directly downloadable in Jpeg (1600 by 10px), DXF and DWG (cad) formats Note The Detail Drawings are applicable to

Suspended Floors All You Need To Know Thermohouse

Ground Floors Archives Detail Library

Part J Suspended Timber Floors Sans Building Regulations South Africa

Underfloor Heating Cooling System For Suspended Floor Systems

1

Floors Dctech

Www Aivc Org Sites Default Files Airbase 107 Pdf

Suspended Floors All You Need To Know Thermohouse

Underfloor Heating Suspended Flooring

Http Www Hyne Com Au Documents Feature documents Tq 18 Timber Floors Recommended Installation Final Pdf

Concrete Vs Timber Floors

Foundations Original Details Branz Renovate

Www Scoilnet Ie Uploads Resources 246 Pdf

Insulating Under A Suspended Timber Floor Insulation Kingspan Great Britain

Technical Hub Insulation Boards Kingspan Ireland

Floors

Insulationcart Com Pdf Tf70 6th Issue Mar 11 Pdf

6 Ground Floors Construction Studies

Techmanual December 13 Website By Jamesjones Sons Issuu

Insulating Below Suspended Timber Floors Ballytherm Co Ukballytherm Co Uk

Suspended Floors All You Need To Know Thermohouse

Concrete Vs Timber Floors

Installing Underfloor Heating With Suspended Timber Floors Thegreenage

Contents Apa Construction Details Full Fill Cavity Walls Partial Fill Cavity Walls Solid Externally Insulated Walls Pdf Free Download

Detail Post Floor Details First In Architecture

Source Of The Old Suspended Timber Floor A Location Of The Building Download Scientific Diagram

1

Timber Flooring

Suspended Timber Floors Insulation Buy In Stirling

Suspended Timber Floor

Floor Detail Drawings

Building Guidelines Underfloor Ventilation Suspended Timber Floors

Insulating Suspended Wooden Floors Wooden Flooring Underfloor Insulation Flooring

Underfloor Heating System For Suspended Floors Underfloor Heating Systems Underfloor Heating Architecture Building Design

2 Level 2 Principles Of Building Construction Information And Comm

Suspended Timber Floor Other Than Ground Floor Insulated Between Timber Joists Quinn Building Products Timber Flooring Flooring Roof Construction

The Different Types Of Suspended Wooden Flooring Construction

Flexural Strengthening Of Old Timber Floors With Laminated Carbon Fiber Reinforced Polymers Journal Of Composites For Construction Vol 21 No 1

Underfloor Insulation Knauf Insulation

The Different Types Of Suspended Wooden Flooring Construction

1

Projects John Butler Sustainable Building Consultancy

Iwi To Suspended Floor Perpendicular Joists Access Below Retrofit Pattern Book

Timber Frame Insulation Designing For Insulation Insulation Ukballytherm Co Uk

What Is A Suspended Timber Floor Discount Flooring Depot Blog

Suspended Timber Floor Detail Youtube

Complete Preservation Home

Wood Floor Section 的圖片搜尋結果 Underfloor Heating Heating And Plumbing Flooring

A Best Practice Approach To Insulating Suspended Timber Floors Ecological Building Systems

Floors And Flooring Sans Building Regulations South Africa

Floor Detail Drawings

Http Isobioproject Com Wp Content Uploads 19 01 Isobio Nb Guide Warm Passivhaus V 2 Pdf

Fbe 03 Building Construction Science Lecture 3 Floor

Sub Floor Perimeter Insulation Vented Shallow Suspended Floor Retrofit Pattern Book

Underfloor Insulation Of Suspended Timber Floors Great Home

Suspended Timber Floor By Bpptech Issuu

Suspended Timber Floors Protection From Termites

Suspended Floor Insulation Saint Gobain Insulation Uk

Diagram Of Suspended Timber Floor With Underfloor Heating Pipes Underfloor Heating Floor Heating Systems Hydronic Radiant Floor Heating

Suspended Timber Floor Detail Youtube

Dct F01 1 Suspended Timber Floor Continuously Insulated Pir Dctech

Diy Conservatory Shop Suspended Timber Floor Base

Insulation Below Suspended Timber Floors Design Guidanceballytherm Co Uk

Suspended Floors All You Need To Know Thermohouse

Flexural Strengthening Of Old Timber Floors With Laminated Carbon Fiber Reinforced Polymers Journal Of Composites For Construction Vol 21 No 1

Suspended Timber Floor Vinsok Ltd

Suspended Timber Floor Construction Studies Q1

Confused Between Joists Or Suspended Floors

Detail Post Floor Details First In Architecture

Building Guidelines Suspended Timber Floors

Floor Insulation Great Home

Flexural Strengthening Of Old Timber Floors With Laminated Carbon Fiber Reinforced Polymers Journal Of Composites For Construction Vol 21 No 1

Installing Ufh Within A Suspended Timber Floor Ambiente

Certified Thermal Details And Products Scheme Bre Group

Technical Detailing By Bhavana Menon At Coroflot Com

Suspended Timber Floor Ybs Superquilt Superquilt Insulation Co Uk

Www Scoilnet Ie Uploads Resources 248 Pdf

Www Scoilnet Ie Uploads Resources 248 Pdf

0 件のコメント:

コメントを投稿